Horizontal Vessels

38750.0 INR/Unit

Product Details:

- Capacity 1000-10000L Ltr

- Tank Material carbon Steel

- Color Grey

- Usage Industrial

- Size Standard

- Click to view more

X

Horizontal Vessels Price And Quantity

- 1 Unit

- 38750.0 INR/Unit

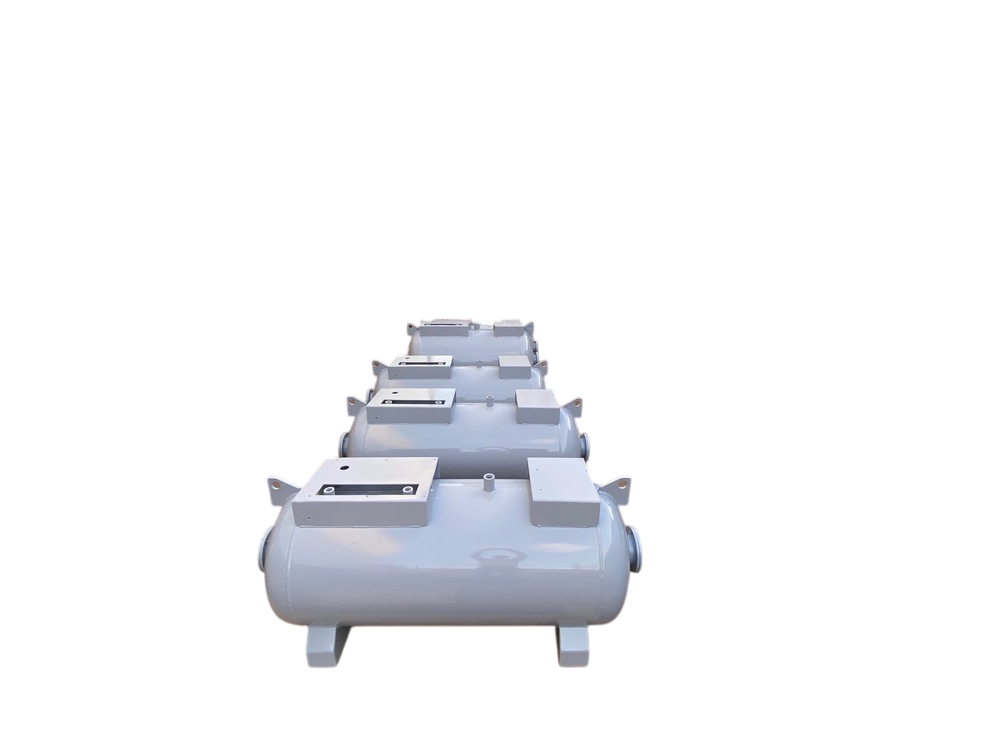

Horizontal Vessels Product Specifications

- Standard

- Grey

- carbon Steel

- 1000-10000L Ltr

- Industrial

Horizontal Vessels Trade Information

- North India

Product Description

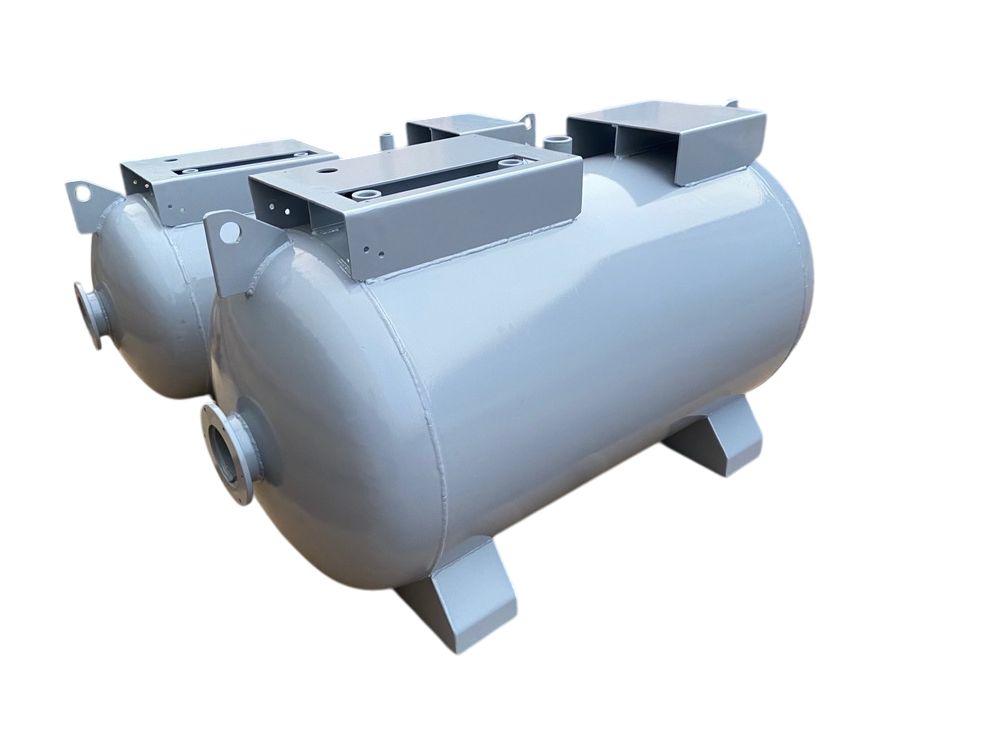

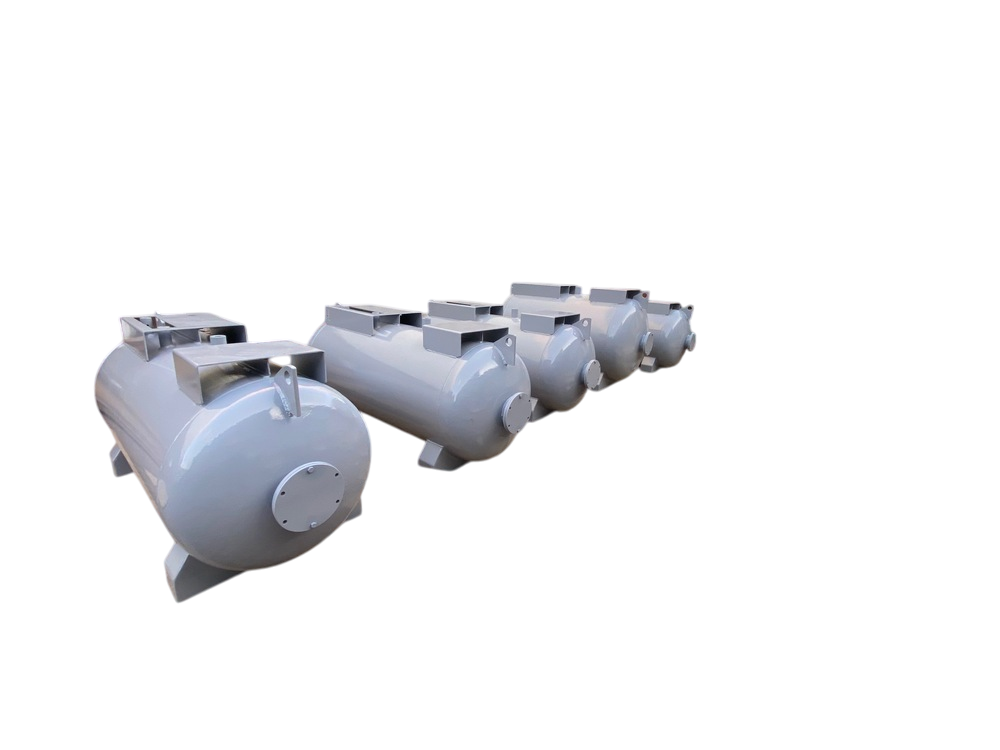

A vacuum tank is a type of industrial container designed to store liquids, gases, or solids under vacuum conditions. The tank is constructed to withstand external atmospheric pressure and maintain a vacuum environment inside. Key Components: 1. Tank Body: A cylindrical or spherical tank made of a suitable material (e.g., stainless steel, carbon steel, or aluminum) to contain the stored material.2. Vacuum Jacket: An outer jacket or shell surrounding the tank body, creating an annular space for insulation and vacuum maintenance.3. Vacuum Pump Connection: A port or flange connecting the tank to a vacuum pump or other vacuum source.4. Vacuum Gauge and Controls: Instruments and controls to monitor and regulate the vacuum level inside the tank. Operating Principles: 1. Vacuum Creation: The vacuum pump removes air and gases from the tank, creating a vacuum environment.2. Vacuum Maintenance: The vacuum jacket and insulation help maintain the vacuum level by reducing heat transfer and minimizing gas leakage.3. Material Storage: The vacuum tank can store liquids, gases, or solids under controlled vacuum conditions. Applications: Vacuum tanks are commonly used in various industries, including: 1. Chemical Processing: Storage of chemicals, solvents, and other liquids under vacuum conditions.2. Pharmaceutical Manufacturing: Storage of pharmaceutical ingredients, intermediates, and finished products under vacuum conditions.3. Food Processing: Storage of food products, such as coffee, nuts, and snacks, under vacuum conditions to preserve freshness.4. Aerospace and Defense: Storage of fuels, lubricants, and other materials under vacuum conditions for aerospace and defense applications. Benefits: The use of vacuum tanks offers several advantages, including: 1. Improved Material Preservation: Vacuum conditions can help preserve the quality and freshness of stored materials.2. Reduced Oxidation and Contamination: Vacuum environments can minimize oxidation and contamination of stored materials.3. Increased Safety: Vacuum tanks can help prevent accidents by removing flammable or explosive gases and vapors.4. Energy Efficiency: Vacuum storage can reduce energy consumption by minimizing heat transfer and optimizing storage conditions. PRICE RANGE: Rs. 50,000 - Rs. 5,00,000FAQs of Horizontal Vessels:

Q: What is the capacity range of the Horizontal Vessels?

A: The capacity of Horizontal Vessels ranges from 1000 to 10000 liters.Q: What material is used to construct the Horizontal Vessels?

A: The Horizontal Vessels are made of carbon steel.Q: In what color are the Horizontal Vessels available?

A: The Horizontal Vessels are available in grey color.Q: What is the primary application or usage of Horizontal Vessels?

A: The Horizontal Vessels are primarily used for industrial purposes.Q: Are the Horizontal Vessels available in customized sizes?

A: No, the Horizontal Vessels are available in standard sizes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email