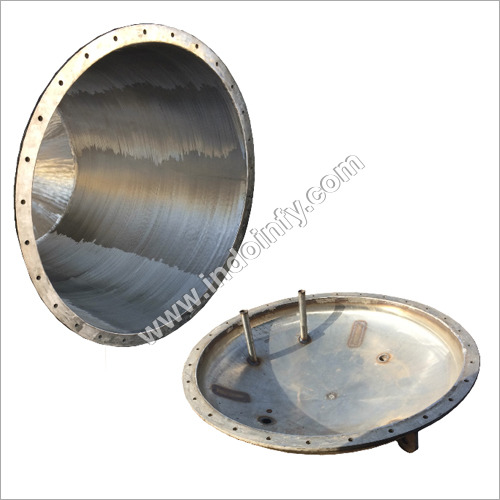

Softener Vessel

135500.00 आईएनआर/Unit

उत्पाद विवरण:

- टाइप करें मृदुकरण पात्र

- उपयोग औद्योगिक

- मटेरियल एमएस

- साइज मानक

- शर्त

- रंग नीला और पीला

- Click to view more

X

सॉफ्टनिंग वेसल मूल्य और मात्रा

- 1

सॉफ्टनिंग वेसल उत्पाद की विशेषताएं

- मृदुकरण पात्र

- औद्योगिक

- नीला और पीला

- एमएस

- मानक

सॉफ्टनिंग वेसल व्यापार सूचना

- , , , , ,

- 7 दिन

उत्पाद विवरण

An industrial softener vessel is a type of water treatment equipment designed to remove minerals and ions that cause water hardness. The vessel uses ion exchange resins to soften the water, making it suitable for various industrial applications.

Key Components:

1. Vessel Body: A cylindrical or rectangular tank made of a durable material (e.g., steel, fiberglass, or PVC) to contain the ion exchange resins.

2. Ion Exchange Resins: Beads or granules that attract and remove calcium and magnesium ions from the water, replacing them with sodium or potassium ions.

3. Distributor System: A network of pipes and fittings that distribute the water evenly throughout the vessel, ensuring maximum contact with the ion exchange resins.

4. Valves and Controls: Automated or manual valves that regulate the flow of water, salt, and other chemicals during the softening process.

5. Regeneration System: A system that periodically regenerates the ion exchange resins with salt or other chemicals to restore their softening capacity.

Operating Principles:

1. Water Flow: Hard water flows into the vessel, where it comes into contact with the ion exchange resins.

2. Ion Exchange: The resins remove calcium and magnesium ions from the water, replacing them with sodium or potassium ions.

3. Softened Water: The softened water is then distributed to the industrial process or system.

4. Regeneration: The ion exchange resins are periodically regenerated with salt or other chemicals to restore their softening capacity.

Applications:

1. Industrial Processes: Industrial softener vessels are used in various industries, such as manufacturing, textiles, and food processing.

2. Boiler Feedwater Treatment: Softened water is used as boiler feedwater to prevent scaling and corrosion.

3. Cooling Systems: Softened water is used in cooling systems to prevent scaling and corrosion.

4. Cleaning and Sanitizing: Softened water is used for cleaning and sanitizing equipment and surfaces.

Benefits:

1. Reduced Scaling and Corrosion: Softened water reduces the risk of scaling and corrosion in equipment and pipes.

2. Improved Efficiency: Softened water improves the efficiency of industrial processes, such as cleaning and sanitizing.

3. Extended Equipment Life: Softened water extends the life of equipment and pipes by reducing the risk of scaling and corrosion.

4. Cost Savings: Softened water can help reduce costs by minimizing the need for descaling chemicals and reducing energy consumption.

PRICE RANGE: Rs. 1,00,000 - Rs. 10,00,000

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email